Some time ago we got in touch

with Steven when he wrote us:

Dear Karin and Bert

I became a certified diver the summer of

1971, however the desire struck in 1961 during my first visit to MarineLand of

the Pacific.

| There while looking

through one of the windows in the large oval tank I saw a man in a smooth,

black, 60ís style wetsuit with a helmet on his shoulders feeding the

fish, I was hooked for good!

It wasnít until just over a year

ago that I found out the name of the helmet he was using, the Miller-Dunn

style 3, I had to have one! And so did many others. Many more trips to the

aquarium were made until itís closing in the early 80ís and everyone

knew where to find me, running up and down the ramps at the large oval

tank making sure I didnít miss anything.

|

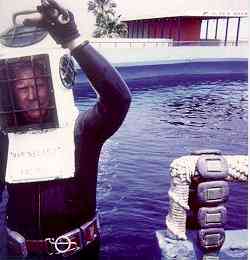

The Miller Dunn Style 3 helmet

that inspired Steve in the 60-ies

|

Now that Iím all grown up (Haaaaa!)

running around the yard with a bucket on my head and the garden hose stuck in

the back were making the neighbors start to wonder.

|

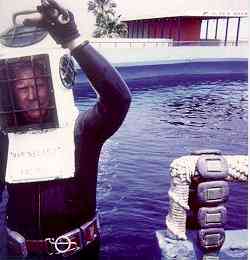

The first test dive: Not only

a home made helmet but also home made tenders ! Steve's sons perform

marvellous !

|

After exploring different

options I couldnít find anything affordable, so here we are with the

prototype Schultz Divinhood. The reason aluminum was chosen for the

prototype was for availability and ease of construction, the soft 6061-0

material formed easily and required no special tooling and allowed for

neat, clean tig weld assembly.

The top domes are spin formed, and

are the only pieces to be outsourced. The light bases and guards are made

from machined aluminum plate and welded to the shell. All weld beads are

blended smooth following test dives and prior to application of corrosion

control. My sons and myself currently make regular dives to just under

60ft as well as several school friends and neighbors.

|

Recently I made contact with an individual, Richard Lowe of Antique Diving

whose excitement for a new project has inspired me to take another

challenge, to reproduce the Schultz hood out of copper and brass.

The new hats will have some minor

changes to facilitate soldering rather than tig welding and some

dimensional changes to the shell and breast plate but will otherwise be

the same as the prototype. Castings for the light bases and guards are in

production and the copper domes are complete and ready to ship.

|

Final valve check

|

You have a great site! If you would like

further detail let me know.

Steve

Well, we are proud to have 21st

century inventors as friends. If you are interested in the copper and brass

version of this helmet, please have a look at our shallow

water helmet collection. Thanks for your contribution Steve.