Introduction

You have seen in the previous

page that NEDU tests and evaluates diving,

hyperbaric, and other life-support systems and procedures, and conducts research

and development in biomedical and environmental physiology. NEDU provides

technical recommendations based upon knowledge and experience, to Commander,

Naval Sea Systems Command to support operational requirements of the United

States armed forces.

Diving helmets

NEDU has developed and produced

many experimental diving helmets. With the fantastic help of Gary L. Harris, we are

proud to be able to share some of them with you. We would be very interested in

any additional material you could contribute. Maybe you have pictures of other

helmets or maybe you can share information on helmets pictured in this section.

# 1

|

|

|

|

|

|

|

This helmet

was made in Lynn Haven, Florida and was a prototype helmet for the US Navy

but the Navy went on to use the Mk12 made by Morse Diving instead. Notice

the similarities between this helmet and the Mk 12. Also notice the

regulator on the back and what looks like two gas connections mounted on

both sides of the back. It has a chin button inside with a lot of other

plumbing installed as well as the comms. It was intended for use with the

neck ring and a neckdam seal. Photo courtesy: Seahawk Company. |

# 2

|

|

|

|

This

attached photo was taken at the Man In The Sea Museum in Panama City,

Florida USA. This is a rare example of George Swindell's earliest

free-flow (open circuit) style dive hat from the middle 1960s. This type

of hat latter evolved into the Advanced 2000 series, also called the

Swindell Hat, Beckman Helmet and even a Beckman-Swindell. The shell was of

hand-laid fiberglass and the metal parts were of machined brass. You can

note that the shell dome is form fitting (like the human head); whereas

latter Swindell hats were more vertical in the back of the shell. The hat

is very much like latter Swindell hats, that is, it is slightly positive

buoyant, it has an interrupted screw thread neck dam, a chin-button style

exhaust and a jocking harness to hold the hat down on the head. George

Swindell had some fiberglass delamination problems with these early hats

and I always found them a bit uncomfortable to work in. I think this

helmet was donated to the museum by the US Navy Experimental Diving Unit

at Panama City. The Navy liked the Swindell hat as it could fit about any

size head. One needs to take only a cursory look at the US Navy SSDS

Mark-12 helmet to see that it was influenced by the Swindell hat. |

# 3

|

|

|

|

This helmet

was donated to the Man In The Sea Museum by the US Navy Experimental

Diving Unit at Panama City Florida. I do not know what the helmet

was called, but it was built in the late 1960s or early 1970s. It has a

fiberglass neck ring that attached directly to a dry suit and connections

for a jocking harness to hold the hat down on the head. The transparent

helmet part is cast from polycarbonate Lexan plastic. I know it is Lexan

as the transparent

shell has bubbles and waves in the plastic. It is very hard to heat cast

Lexan (as the Navy must have found out), because when you get it hot

enough to mold it

will bubble up. This hat is an interesting but failed idea. |

|

|

|

# 3 about to go down.

Official US Navy photo |

# 4

|

|

|

|

No, this

helmet is not proof that Darth Vader served in the US Navy in the 1960s.

It is an experimental diving helmet made for the Naval Coastal Systems

Laboratory (Experimental Diving Unit) at Panama City, Florida. It was

donated to the Man In The Sea Museum. If you look carefully it uses many

of the same

brass fittings that the latter Navy SSDS Mark-12 helmet used. It also is

designed to be used with a mixed-gas recirculator backpack. The fittings

on the back

of the hat are for flex hoses to connect to the back pack. the helmet

shell is fiberglass. I think this is the ugliest helmet I have ever laid

eyes on. |

# 5

|

|

|

|

This is

another experimental diving helmet from the EDU. I think it was built and

tested in the 1970s. It is an interesting configuration, but it is also

the second ugliest helmet I have ever seen. The shell is fiberglass and

the parts are of machined brass. The hat is a demand style helmet so it is

close fitting and has a demand regulator. I do not know who built the hat

for the EDU, perhaps Morse. If you look carelfully at the photo you can

see that it too has

fittings that share features with the latter SSDS Mark-12 Navy helmet. So

the Navy must have borrowed the features from this, and other helmets that

it

liked, and put them in the SSDS Mk-12. The front facepiece port comes off

and is held on with moveable pins just like the neck dam of the SSDS

Mk-12. The nose clearing device inside the hat is machined from brass, and

the hat has a side block air intake assembly not unlike that style seen in

latter Kirby-Morgan demand type hats. |

# 6

|

|

|

|

This is the

KMCSH-4. It was an early semi-closed mixed gas experimental hat built for

the EDU by the Kirby Morgan company in the middle 1960s. The

Westinghouse Oceanic Division designed the experimental backpack

helium-oxygen deep diving recirculator for the rig. Most people know

Westinghouse as the builder of kitchen appliances, but in the 1960s and

70s they built experimental life support systems for underwater and outer

space. Oddly enough they also built a few experimental stainless steel

diving helmets with neck dams. I don't have a picture of any of the

Westinghouse hats, I think only one or two were built. According to Joe's

Savoie's wife (Joyce) Westinghouse engineers got Joe to act as their

consultant (unpaid) and then they refused to give him any credit for

influencing their helmet design. Anyway back to the KMCSH-4, which is now

on display at the Man In The Sea Museum in Panama City, Florida USA. The

hat is a fiberglass clamshell design. This simply means that it sealed

around the diver's face and the helmet dome held the full face mask tight

to the diver's head. Inside it is equipped with an oral-nasal mask. The

side connections are for the hoses to the mixed gas recirculator. This hat

was not very successful. |

# 7

|

|

|

|

This is the

KMCSH-6. It was the final version of Kirby-Morgan's clamshell helmets. It

was built for the EDU and the SeaLab Program in the middle 1960s.

None of the Clamshell designs worked very well so they were abandoned. It

is fiberglass with a hinged head protector. The mask was built primarily

for a

mixed-gas recirculator, but you can see in it features that were latter

employed in the Kirby-Morgan Band Masks. |

# 8

|

|

|

|

This mask is

on display at the Man In The Sea Museum. Some people claim this is the

Kirby-Morgan MM-3, and it may be. Others say it is an early General

Aquadyne rigid frame full-face mask (it is not a band mask). It has many

of the features of the early General Aquadyne masks. The mask has a

fiberglass frame with a sponge rubber face seal. The demand regulator

looks to be the ScubaPro model, like GA used. It is equipped with an

oral-nasal mask with microphone and the frame is fitted with ear speakers,

again as used by GA. The helmet dome is a padded head protector. I

dove these masks many years and found them to work well. occasionally one

still sees a General Aquadyne mask around the job site. |

# 9

|

|

|

|

This is an

experimental diving hat built for the EDU by Morse Diving Equipment co. I

don't know the exact date of manufacture, but I suspect the 1970s or

early 80s. It is on display at the Man In The Sea Museum. The influence of

the early Kirby-Morgan helmets is obvious. This hat, which is designated

PN:

608-5168070, and SN: ADI or AD1, has a KMB superflow regulator

attached to dual hoses intended for a backpack mixed gas recirculator. The

shell is fiberglass with machined brass fittings. |

|

|

|

|

This is

another view of the experimental Morse demand hat. You can see that the

neck dam is held in place by a couple of cams with brass handles, and the

helmet is secured to the diver's head by a unique, adjustable brass slide

retainer that was obviously influenced by the Kirby-Morgan toilet seat

(retainer).

The cams are kept from coming unattached to the neck dam by pins not

unlike those on the SSDS Mk-12 neck dam. An interesting feature inside the

hat is that the head pad can be adjusted by an external handle on the port

side of the hat; this feature is a copy of the General Aquadyne DMC-7 head

pad securing

system, an excellent innovation. |

# 10

|

|

|

|

This is a

homemade free-flow style diving helmet on display at the Man In The Sea

Museum. I do not know who gave it to the museum or who made it. It has a

crude, hand laid fiberglass shell with a thick lead ring at the bottom

that secures a permanently attached neoprene neck dam. The shell is padded

inside and

also has some lead in it. The intake valve is a commercial off-the-shelf,

stainless steel Whitey needle valve. The outlet valve is an adjustable

DESCO

exhaust valve (from a DESCO pot). The faceport must have been cut from a

sheet of 6 mm thick Lexan. The hat was held on the diver's head by a jock

harness. In the early days of commercial oil patch diving in the Gulf many

divers simply could not afford, or could not find a neck dam style hat, so

they made their own. This lead to some rather strange innovation. I

knew one diver who cut out the bottom of a pressure cooker and put on a

fiberglass top and faceport. He then cut out the center of the lid and

permanently attached a ring of lead and bolted on a rubber neck seal. Once

he attached some fittings it worked pretty well (I dove it), but it was

not the type of rig I would recommend be used by amateurs. PS, don't try

this at home. |

# 11

|

|

|

|

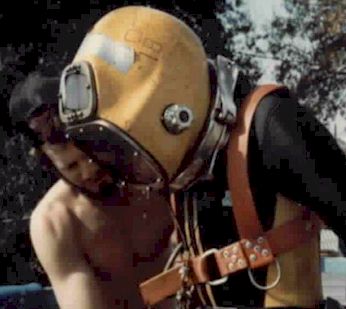

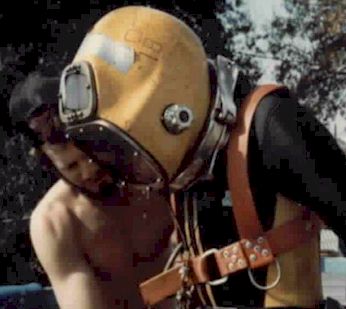

This is me

while I was in dive school at the Ocean Corporation at Houston, Texas. I

have been told that this mystery helmet is a version of the Rat Hat, but

it seems to have none of the features of the earlier Rat Hat. This

free-flow hat belonged to the Ocean Corp. and we used it in the burning

tank (underwater welding and cutting). The shell is/was fiberglass with

chrome plated brass fittings. It had good balance and dove well. The neck

dam had a couple of cam handles and the neck ring sealed on an O-ring. It

used a jock harness to keep the hat down on the diver's head. Can anyone

out there identify this hat? |

# 12

|

|

|

|

This is

another experimental helmet built for the Experimental Diving Unit by

Morse Diving Equipment Company. It dates to the mid 1970s.

The regulator is very close in design to the US Divers valve as is the

side block valve assembly.

|

|

|

|

The shell is

made of yellow fiberglass and the metal parts are chrome brass and

bronze. |

All text and

pictures in this section, except #1 and #12 are by courtesy of Gary L. Harris

- Last update: 1st February

2013