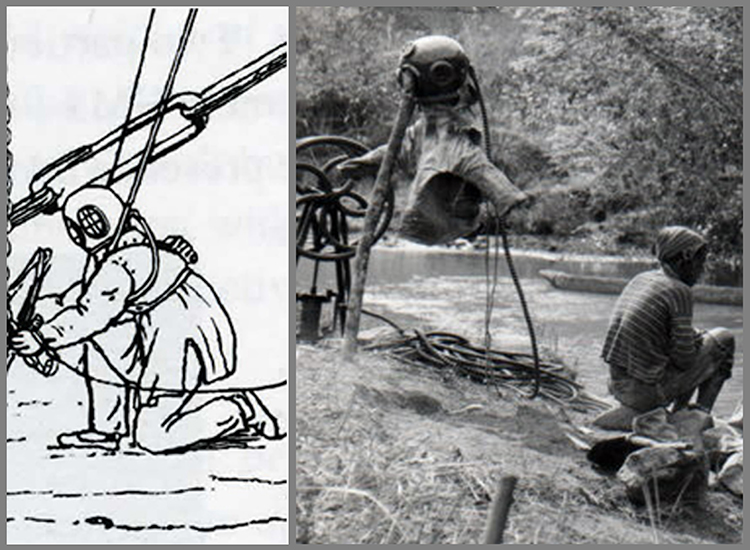

Above left - Deane Brothers ‘Open water dress’ circa 1830s Above right - Person ‘Open diving dress’ used for alluvial diamond work in a South American River.

By Mike Burchett and Robert Burchett ( Historical Diving Society).

Introduction

It can be argued that the concept of an ‘open diving dress’ was nothing new by the early 1900s, and the Deane Brothers had been using their open diving dress with success since it was invented by them back in 1829. Their open diving dress was manufactured by Augustus Siebe and pre-dated the closed diving dress which kept water out completely. Even during the 20th Century some old closed diving dresses were occasionally cut at the waist and converted into an open version for tasks in rivers and for some pearling work.

Above left - Deane Brothers ‘Open water dress’ circa 1830s Above right -

Person ‘Open diving dress’ used for alluvial diamond work in a South American

River.

However,

the open diving dress was a surface supplied system, with air being pumped down

to the diver through a hose. The ‘Hall-Rees Patent Independent Breathing

Apparatus’ and the ‘Patent Self-Contained Life-Saving Apparatus’ were Siebe

Gorman’s early examples of simple independent breathing apparatus (free of

surface air supply) which could be adapted for a variety of purposes including

submarine escape, as a smoke helmet and an open diving dress for shallow water

use (for depths less than 30ft.) Although the equipment was adopted by the

Admiralty around 1909, by the late 1920s the Hall-Rees apparatus and others of

its type had been superseded by better escape and rescue equipment such as the

Davis Submerged Escape Apparatus (DSEA).

During the early 1900s, submarines and submarine warfare was becoming firmly

established among various navies. In 1904 Great Britain created the Royal Navy

Submarine Service with a shore establishment of HMS Dolphin situated at Fort

Blockhouse in Gosport.

HMS Dolphin shore establishment , circa WW1 . Photo Vice Admiral Sir Cyril

Ponsonby

The rapid development of submarine warfare lead to increasing numbers of submarine losses and accidents. The mounting death toll among submariners began to cause real concern and by 1907 the Admiralty began looking more seriously into the possibilities of developing an escape apparatus for use by trapped submarine crews. This would help to improve morale and submariners would no longer be left to a watery fate without some hope of escape.

At this time Siebe Gorman & Co. Ltd. was producing underwater equipment both for military and commercial purposes and already had an established working relationship with the Admiralty. Under the leadership of managing director Robert H. Davis, the company was constantly producing a wide range of innovative products, and was well placed to research and develop any new apparatus required for military and commercial purposes.

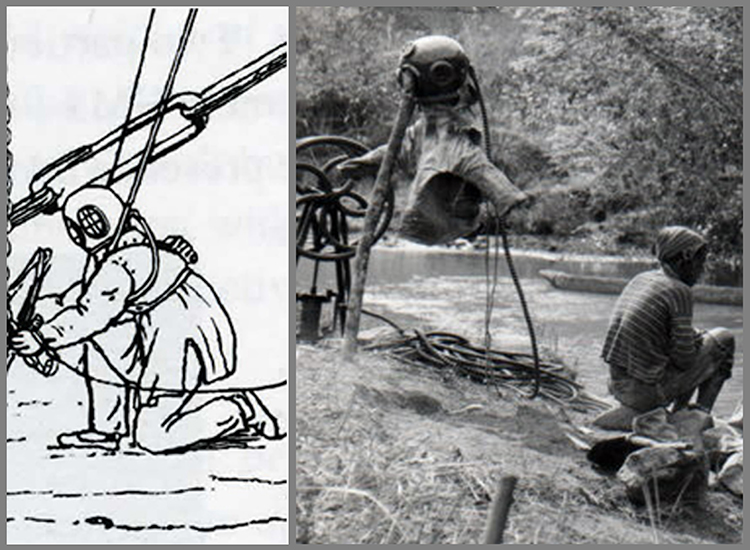

Augustus Siebe (1788-1872) Company founder. Sir Robert Henry Davis

(1870-1965) Managing Director of Siebe Gorman & Co. Ltd.

Henry Albert Fleuss (185101933) Designer of the first practical ‘Self-contained

breathing apparatus.

The

early days ….

In 1904 R.H. Davis designed a simple submariners’ escape apparatus consisting of

a hood attached to an open jacket with fitted cuffs, all made from a light

flexible waterproof material. The apparatus was held securely in place by a

waist-belt and crotch-strap. A valve on a small cylinder of compressed air (120

atmospheres) was housed in the jacket pouch and could be opened to feed air into

the top of the hood.

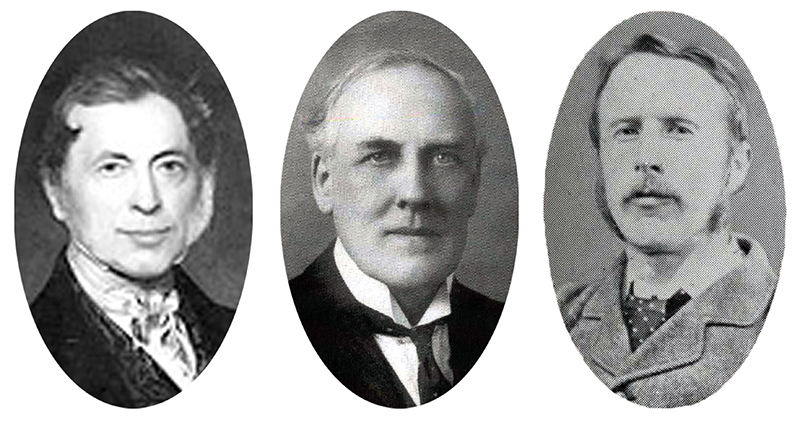

Early examples of submarine escape apparatus. (Left) R.H. Davis 1904 design

with soft hood, open jacket and compressed gas cylinder for breathing.

(Middle) Hall-Rees-Davis 1908 adopted design with purifier/oxygen generator and

metal helmet.

(Right) H.A. Fleuss & R.H. Davis 1905 design that could also be used for shallow

water diving.

This kept the level of water down inside the open jacket and below the wearer’s mouth. The wearer used a mouthpiece connected to a small open breathing tube that led from the inside top of the hood. This enabled the wearer to draw breath even if the water level reached above the mouth. A nose-clip could be worn. An inflatable belt was included in the equipment which could be worn high up under the arms, so when reaching the surface it would keep the person afloat and allow the front window to be opened for fresh air. In later designs the inflatable belt was replaced by a buoyancy chamber that was integral to the jacket and had the option of being inflated from a small compressed gas cylinder. This early design was not taken up by the Admiralty, but many of the features were incorporated into later apparatus adopted by the Royal Navy Submarine Service and lesser foreign navies.

In 1905/06, another attempt to produce a workable escape apparatus was made by H.A. Fleuss & R.H. Davis. This time they used two compressed oxygen cylinders, a regulator to control the gas flow, and a carbon dioxide absorbent canister carried on the back of the wearer (fig.4). The system was connected to a flexible hood and the apparatus was held in place using cross-shoulder and underarm straps. Two integral inflatable buoyancy chambers on the front and back of the jacket kept the wearer vertically afloat on reaching the surface. This apparatus proved too bulky for submarine use, and doubts existed about the submariner’s ability to exit through the upper conning hatch of a submarine while wearing it. Despite its possible use, a set for each crew member would take up too much space in the cramped confines of a submarine, therefore it was not adopted by the service. However, it could be modified for shallow water diving purposes by using hanging weights on hooks fitted to the jacket and ankle pocket weights to maintain the diver’s balance. It is not known if this apparatus was commonly used.

Another important discovery took place during 1904 which was to change future designs of escape and rescue apparatus. The chemist Professor Georges Jaubert invented preparations of sodium and potassium peroxides which gave off oxygen when in contact with moist air, while at the same time the alkaline bi-product from the chemical reaction absorbed the carbon dioxide. Unfortunately a disconcerting problem with peroxides was the tendency to self-ignite in the presence of too much water. It could also burn moist skin and the alkaline residue was caustic, so the peroxide preparations had to be treated with great caution. Jaubert’s preparations were patented in France and a more stable granular preparation of potassium peroxide (called Oxylithe) could be activated by moisture in expired breath. The Vickers family (Barrow shipbuilders and submarine manufacturers, plus majority shareholders of Siebe Gorman & Co. Ltd.) made R.H. Davis aware of these preparations. Seeing their potential, Davis quickly bought the rights from the French manufactures that same year.

During 1907 two British Naval officers, Captain (later Admiral) Sidney Stewart Hall, C.B.E., and Fleet-Surgeon Oswald Rees, M.D. (of HMS Mercury) in collaboration with RH Davis (of Siebe Gorman) came together to produce a workable escape apparatus. This time, with knowledge from previous attempts and the rights to use the Oxylithe preparation, a suitable apparatus was soon developed. After some modifications the Hall-Rees-Davis design, called the ‘Hall-Rees Patent Independent Breathing Apparatus’, was patented on 18th August 1908 (US Pat. 896447A). After extensive trials it was quickly adopted by the Royal Navy and on 22nd June 1910 the Admiralty announced that all sea-going submarines (47 in total) had been completely supplied with the new life-saving devices … “sufficient in number for the entire crew”.

Crew of HM Submarine C7 training with Hall-Rees escape apparatus, circa 1909.

The apparatus jacket was equipped with an inside buoyancy chamber at the front

and oral inflation tube. Once inflated the window could be opened at the

surface. The 1910 illustration by G.H. Davis during the King’s visit depicts and

ideal situation inside the submarine, which in reality would be far more

cramped!

Submarine air-lock spaces were also provided in which the crew could don the apparatus. The fact that Oxylithe dispensed with the need for compressed gas cylinders as the main supply of breathable oxygen probably influenced the Admiralty in adopting the apparatus for the Submarine Service.

The new Hall-Rees apparatus incorporated some variations depending on its role as a smoke helmet, an escape apparatus or as shallow water diving apparatus.

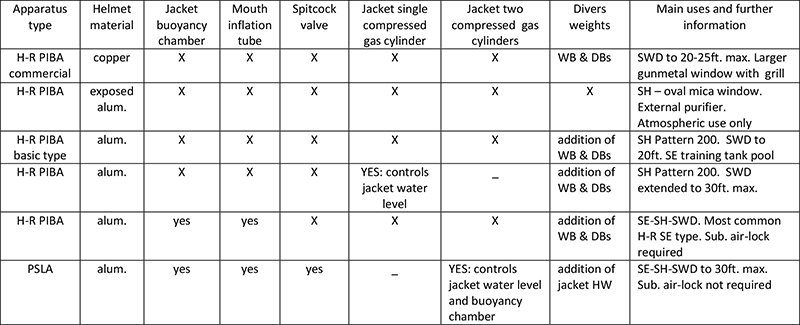

Types of Hall-Rees-Davis Independent Breathing Apparatus.

Abbreviations: aluminium (alum.); weight belt & divers boots (WB & DBs); jacket

hanging weights (HW); shallow water diving (SWD); smoke helmet (SH);

submarine escape (SE); absent (X); Hall-Rees ‘Patent Independent Breathing

Apparatus’ (H-R PIBA); ‘Patent Self-Contained Life-Saving Apparatus’ (PSLA);

submarine (sub.)

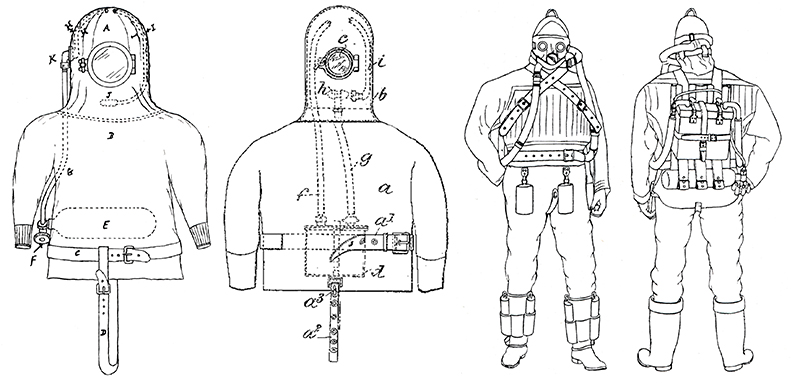

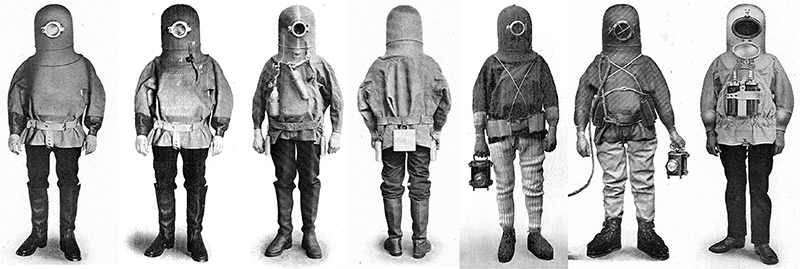

Catalogue versions of Hall-Rees Apparatus adapted for different purposes. (From

left): 6a. Standard unmodified Hall-Rees apparatus.

6b. Common version with built-in buoyancy chamber and oral inflation tube. 6c.

‘Patent Independent Life-Saving Apparatus’

(front and back views) with compressed gas cylinders and additional hanging

weights for shallow water diving to 30ft.

6d. Standard Hall-Rees apparatus (without buoyancy chamber or waterproof

trousers) equipped with weight-belt and lead boots for shallow water diving to

20ft.;

6e. Commercial Hall-Rees shallow water diving apparatus (max. depth 25ft.) with

large grill window and helmet made of copper.

6f. Smoke helmet with large oval window and external purifier container

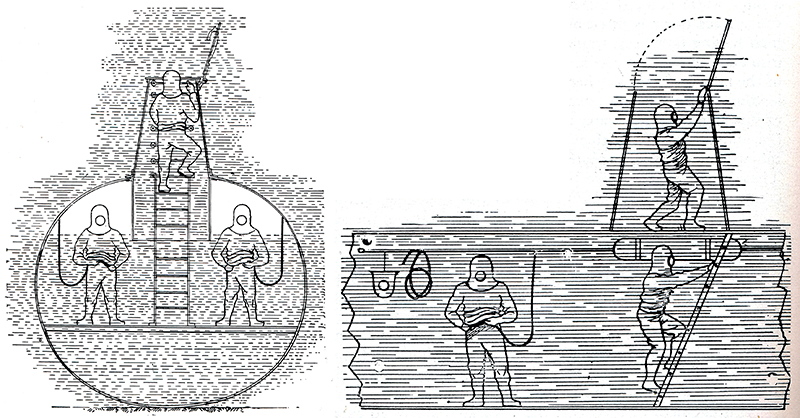

The new Hall-Rees apparatus incorporated some variations depending on its role as a smoke helmet, an escape apparatus or as shallow water diving apparatus Submarine escape apparatus also varied slightly depending on what the class of submarine could offer as far as numbers and type of escape compartments with hatches, and air-locks or air-trap spaces where submariners could put on the apparatus and wait their turn to escape. Published illustrations depict the escape apparatus neatly hanging in rows from the bulkheads in readiness for use, but in practice it is more likely they were stored wherever there were convenient spaces within the cramped confines of the submarine’s compartments. ‘Compartment escape’ involved flooding the whole compartment until the air was compressed and the water ceased to rise. A trunk was then attached or lowered from the base of the escape hatch until it rested beneath the surface level of the water. Valves allowed the trunk to be completely flooded, at which point the hatch could be opened without releasing the compartment’s air pocket. Donning their escape apparatus, the crew members ducked under the trunk one at a time, entered the tube and ascended to the surface.

Sectional illustrations of a submarine. (Left) Men using compressed air-lines in

air-lock spaces awaiting their turn to escape through

conning tower. (Right) Men escaping from submerged compartment and using an

air-line to reduce the water level inside the jacket

If air-locks were not installed then a compressed air-line was pushed up under the jacket and opened, enabling the wearer to keep the water level about half way down inside the Hall-Rees jacket. A temporary 12lb. weight attached to the front waist belt of the jacket helped the submariner to keep down while moving from the air-lock to the place of escape. The weight could be jettisoned if the wearer was too heavy underwater or once the surface had been reached. Escape apparatus could be donned in about 30 seconds without assistance. Practice in donning the apparatus and using it was carried out in a specially constructed tank at Portsmouth.

The tank had a lowering/raising air-lock platform seat and a skeleton submarine conning tower escape hatch on the bottom.

Submariners practicing submarine escape in the specially constructed training

tank at Portsmouth, circa 1910

The Apparatus…

the standard Hall-Rees design consisted of a light domed aluminum helmet with a small hinged front window that was watertight when shut. A rigid helmet was chosen instead of the earlier flexible hood as it offered increased protection to the wearer if accidental contact was made with a surface object during rapid ascent.

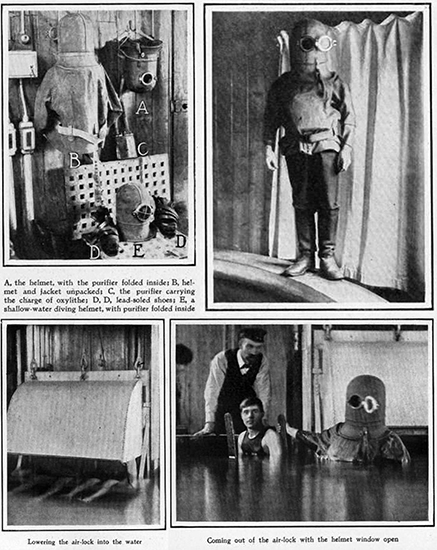

Hall-Rees-Davis ‘Patent Independent Breathing Apparatus’. (Left) Standard

type without buoyancy chamber. (Middle & right)

The ‘Patent Self-Contained Life-Saving Apparatus’ … aluminum helmet without

canvas covering and various fittings.

The helmet was large enough for free inside head movement and flared out to fit the shoulders for a more comfortable fit. Inside the helmet were two small metal beckets for tying off the purifier breathing tubes in the correct positions. The outside surface of the helmet was normally covered in a single layer of canvas twill (perhaps to cushion the helmet and prevent unwanted noise when stowed in submarines). A short waist length jacket (open at the bottom edge) was permanently attached to the helmet rim inside and out, and was made from double layered waterproof canvas twill (as used for standard diving dress). The ‘one-size-fits-all’ jacket had an eyelet waist-belt and crotch-strap fastened to a front hook to secure the jacket and prevent it rising up the wearer when inflated. The sleeve ends had waterproof India rubber cuff seals (as per standard diving dress). Inside the front of the jacket was a pocket to house the purifier. The complete apparatus weighed 16lbs. and could be stored in a space measuring 12x12x16 inches with the jacket and purifier folded into the helmet. However, it is unclear whether jackets with additional compressed gas cylinders could be contained within the helmet (see later).

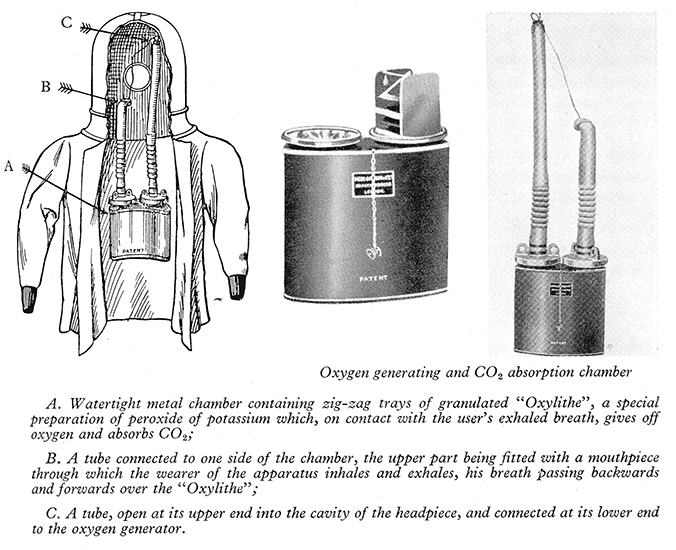

The thin metal purifier/oxygen generator canister containing the Oxylithe consisted of two removable internal chambers linked across the bottom by a tube. Each chamber had a number of trays arranged in a zigzag fashion, onto which the Oxylithe granules were thinly spread. Each chamber was locked down with a watertight screw-cap that had a central connection for the breathing tube. To one connection was fitted a shorter rubber tube with mouthpiece, and to the other a longer rubber tube which led into the upper part of the helmet (the end of this tube being open).

Purifier and oxygen generating canister containing the ‘Oxylithe’

preparation.

The ends of the rubber tubes had removable stoppers which sealed them when not in use, otherwise damp air would prematurely activate oxygen release and render the apparatus unusable. Expired air passed through the chambers through the longer tube and into the top of the helmet. Then as the wearer breathed in, air was sucked back down the longer tube and so passed a second time through the canister, removing further carbon dioxide and adding more oxygen … therefore the air was double-purified. If the wearer became breathless due to over-exertion, then a couple of minutes rest normally brought breathing under control.

Hall-Rees-Davis apparatus used in submarines and for shallow water diving had an insulated (double-walled) purifier canister housed in a pocket inside the front of the jacket. It was thought this gave better protection from snagging and the chemical reactions would be less affected by cold water. The simplest design of escape apparatus had a mouth tube inside the helmet to inflate the internal buoyancy chamber of the jacket when the wearer reached the surface, and an external valve could be turned shut to prevent air loss. This was crucial as the jacket would lose buoyancy once the window had been opened for fresh air. However, getting enough air into the buoyancy chamber by mouth must have been awkward once on the surface. This Hall-Rees design with the oral inflation tube appears to be the most common for submarine use, probably because it was simple, fulfilled the various requirements and did not require any additional compressed gas cylinders (fig.9).

Other design arrangements included the use of one or two compressed gas (air or oxygen) cylinders housed in external jacket pockets. The single cylinder arrangement allowed the jacket’s buoyancy chamber to be quickly and safely inflated at the surface. With the two cylinder arrangement the larger upright cylinder was used to keep the water level inside the helmet down to a safe level, while the other cylinder was used to inflate the buoyancy chamber at the surface. A central spitcock valve below the window was found on apparatus that used the two cylinder arrangement. This was probably used for fine buoyancy control and perhaps de-misting using mouth ingested water as per the standard diving helmet method. Hooks on the jacket allowed lead diving weights to be suspended on the jacket (figs.6c & 9). This apparatus was known as the ‘Patent Self-Contained Life-Saving Apparatus’ which could be used for shallow water diving to 30ft. as well as submarine escape.

Hall-Rees smoke apparatus did not require gas cylinders or a buoyancy chamber to function, but just the purifier. However, the navy likely used their Hall-Rees breathing apparatus for combined usage (e.g. for smoke, foul air or poisonous atmospheres inside a submarine such as release of chlorine gas, submarine escape and shallow water diving usage). The commercially available version of the Hall-Rees smoke helmet was different in that it had the purifier/generator canister mounted on the outside of the jacket to keep the wearer and canister cooler and less encumbered. This helmet had a characteristic large oval hinged window (similar looking to that found on the Siebe Gorman Mines Recovery Suit some 40 years later at the end of WW2) but the window glass was replaced with mica (fig.6f).

Apparatus used for diving purposes…

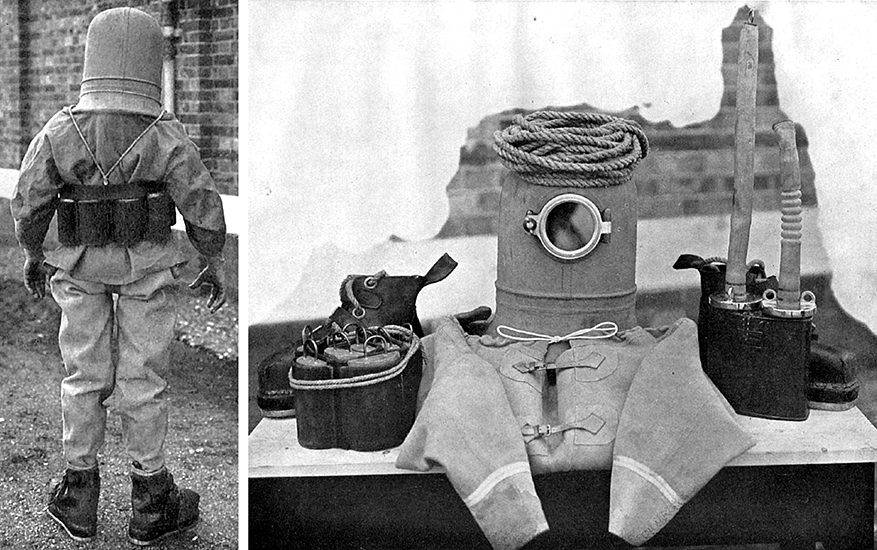

Both the ‘Hall-Rees Patent Independent Breathing Apparatus’ and the ‘Patent Self-Contained Life-Saving Apparatus’ (those with two compressed gas cylinders and hanging jacket weights) were used for various shallow water diving tasks including hull inspections, clearing fouled propellers, Kingston valve maintenance and any other light underwater work (figs.6c & 6d). Both arrangements used Oxylithe from the purifier/generator to supply the diver with breathable oxygen for about 40 minutes on a single fill. This could stretch to about an hour at surface pressure. When used for shallow water diving, this version of the Hall-Rees apparatus weighed about 105lbs. It became known as the ‘Pattern 200 smoke helmet and shallow water diving equipment’ and was probably the most useful and readily available arrangement of open dress for RN divers.

Hall-Rees ‘Pattern 200 smoke helmet and shallow water diving equipment’ which

includes jacket/helmet, purifier, weighted belt, divers boots and life-line.

The set

included the helmet with jacket and purifier (16 lbs.), a pair of lead-soled

shallow water boots (24 lbs.) and a weight belt of 65 lbs. Heavier standard

diver’s boots of 36 lbs. could also be worn with a less heavy weight belt of

about 53 lbs. to improve the diver’s balance. The jacket/helmet was of the

normal arrangement without buoyancy chamber or compressed gas cylinders, but did

have two additional ‘strap & buckle’ fastenings across the chest to help draw in

the jacket.

Without compressed air, a maximum diving depth of about 20-25ft. was the safe

limit due to the of rising level of water inside the jacket. When an additional

single compressed gas cylinder arrangement was used to reduce the water level in

the jacket a deeper depth of about 30ft. could be achieved and this also

happened to be the safe maximum working depth for a diver breathing pure oxygen.

In cold water, a one-piece waterproof under-suit (open at the neck) could be

worn under the ‘Pattern 200’ jacket (and with other Hall-Rees diving outfits) to

keep the diver dry and warm. This could be dispensed with in warmer waters. The

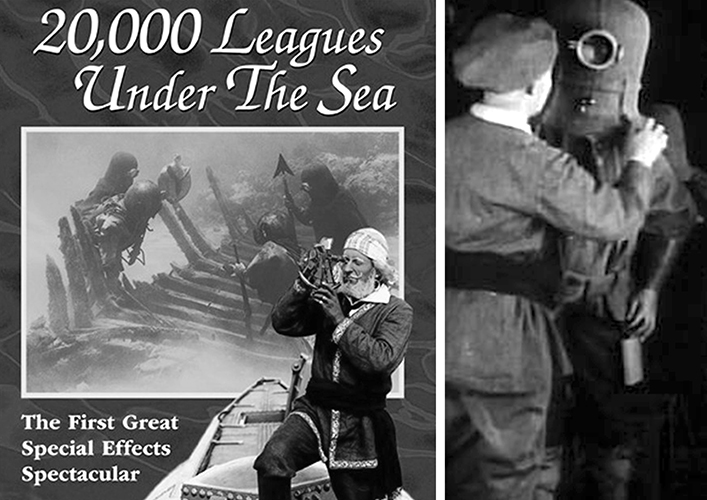

‘Patent self-Contained Life-Saving Apparatus’ was used by John Ernest Williamson

to equip some divers of the Nautilus for the 1916 film version of Jules Verne’s

classic story, ‘Twenty Thousand Leagues Under the Sea’.

Divers using the ‘Patent self-Contained Life-Saving Apparatus’ with hanging

jacket weights in the 1916 film version of ‘20,000 Leagues Under The Sea’.

J.E. Williamson again used the same type of apparatus in the classic 1921 film ‘Wet Gold’.

Siebe Gorman and Royal Navy Diving Manuals (1909, 1910 and 1916) gave basic instructions in dressing and use of the Hall-Rees ‘Pattern 200’ shallow water diving equipment. The diver first put on the waterproof under-dress (if required) then the diver’s boots. The jacket was pulled out from inside the helmet and the plugs removed from the ends of the purifier’s two breathing tubes. While seated, the wearer put his arms through the sleeves and the rubber cuffs formed a watertight seal around the wrists. He then lifted the helmet over his head (window open) and the shorter breathing tube was placed in the mouth. Some deep blowing into the breathing tube removed any caustic dust, and at the same time moist exhalations soon started oxygen production from the chemical reaction (the wearer was advised not let go of the mouthpiece as it was difficult to replace once the window was fastened shut). Breathing was carried out through the mouth and not through the nose, otherwise oxygen production could fail, so a nose-clip could be worn to prevent this. When standing, the life-line was attached to the diver’s waist and tied off near the helmet, then a weighted belt was put on last of all. The front window could then be shut.

In case of an underwater emergency, removable pocket weights from the weighted belt (or the entire weight-belt itself) could be jettisoned, so the diver would simply rise to the surface. However, boots were never to be removed underwater with the weight belt still on as this could easily have led to inversion and drowning. Without an additional compressed air cylinder, the amount of air a diver could take down was the volume of air trapped in the jacket/helmet from the surface, and the deeper the diver descended the higher up the water level rose inside the jacket as the air became compressed upwards into the helmet. The Oxylithe purifier did not add any additional volume of gas to the suit. If too buoyant, the diver either added more weights or vented a little of the excess volume by opening a cuff seal, so allowing the gas to bubble out. However, vent too much and the water level inside the jacket became too high, especially if the wearer was slightly bent over. Under these circumstances there was no choice except to come up to the surface and collect more jacket air. Divers using the apparatus were recommended to be positively buoyant and pull themselves down a shot-line a few fathoms until they had reached their working depth. Then if they were still too buoyant, a little excess air could be released from the cuffs until neutral buoyancy was achieved. While underwater, the diver had to maintain the helmet in an upright position, as bending over could release the trapped jacket air, cause the jacket to flood, and in the worst case scenario … drowning due to helmet flooding. To pick up an object a diver had to adopt a kneeling position. The diver was linked to the surface tender by a stout life-line worn around the waist and stopped near the helmet to prevent accidentally inversion while being pulled to the surface. The tender monitored the diver’s time and did not let him exceed the recommended limit of 40 minutes. Generally the diver was gently and slowly pulled to the surface by the tender, so the life-line was mainly used for communication (e.g. using hand pull-signals). Oxylithe was replaced after every dive according to the recommended procedure.

Examination of surviving helmets…

When the commercially available Hall-Rees ‘Independent Breathing Apparatus’ was used as a ‘Shallow-Water Diving Dress’ it was slightly different to the ‘Pattern 200’ version used by the Navy. Characteristically, the helmet was made of copper with a larger diameter gunmetal window for better vision, and fitted with a protective cross-wire grill. Of the five known examples, three still have jackets attached.

Surviving Hall-Rees ‘Independent Breathing Apparatus’ for shallow water

diving use. Unlike the ‘Pattern 200’ equipment used

by Royal Navy, this commercial version had characteristic differences including

a copper helmet and larger window with cross-grill.

None of the helmets have inlet holes for cylinder-fed gas pipes (blanked) and their jackets have no buoyancy chamber (but all do have the internal breast pocket to house the purifier canister). Unsurprisingly, a commercially available shallow water diving dress helmet would need to be more robust and last longer than the majority used by the Royal Navy for a ‘one-off’ submarine escape situation which was their primary function.

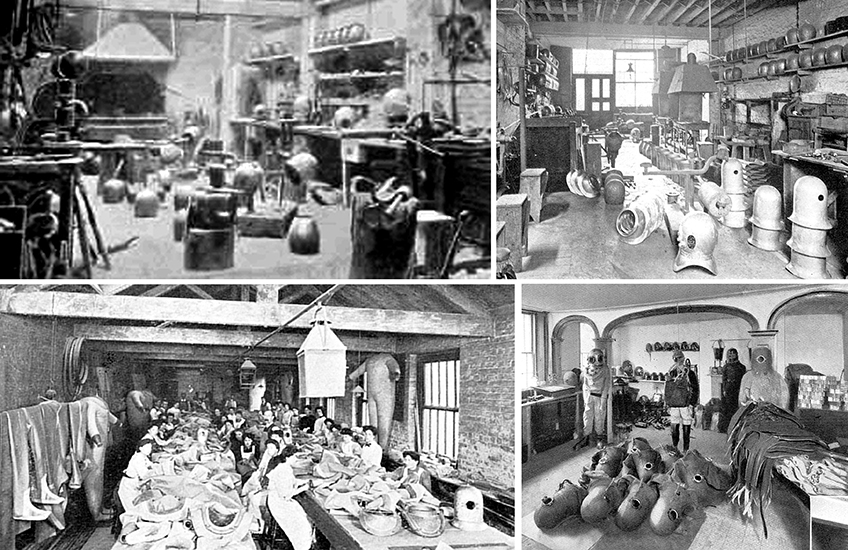

It is not possible to accurately determine the numbers of Hall-Rees apparatus made by Siebe Gorman & Co. Ltd. for both military and commercial uses. However assuming the 1910 press statement from the Admiralty that 47 submarines were completely supplied with the life-saving apparatus and with 25 helmets per submarine quoted elsewhere, an estimate of 1175 helmets of the aluminum type can be estimated. Siebe Gorman was therefore capable of manufacturing and supplying a large quantity of units quickly and the company even set up a dedicated department for this purpose.

Production of Hall-Rees-Davis apparatus at Siebe Gorman’s ‘Neptune’ Works,

Westminster Bridge Road, Lambeth, London S.E.

(Top left) Coppersmith’s workshop. (Top right) Helmet fitting workshop. (Bottom

left) Diving dress workshop. (Bottom right) Submarine escape apparatus shop and

store.

How many more helmets were made between 1910 and 1927 is not known? However, serial numbers on surviving Hall-Rees jackets (775T, 2209 & 2255) indicates that a few thousand may have been produced over the 17 year time span. Considering the numbers of British submarines in service at Armistice in 1918 (137 serving submarines and 78 under construction) these estimates seem quite feasible. Apart from the three surviving Hall-Rees-Davis apparatus at the Royal Navy Submarine Museum, Gosport, it is probable that the Navy’s entire stock was scrapped with the introduction of the DSEA around 1927. Only a handful of Hall-Rees shallow water diving equipment made for commercial use (e.g. helmets of copper with a larger grilled window) have survived. Production numbers for these helmets were probably low as they were of limited use for commercial diving in cold British waters and their underwater duration was limited.

Conclusion

The ‘Patent Self-Contained Life-Saving Apparatus’ and the ‘Hall-Rees-Davis Patent Independent Breathing Apparatus’ were similar apparatus, developed mostly for military purposes and adopted by the Admiralty for various uses such as submarine escape, breathing in poisonous atmospheres and for simple shallow water diving work. The basic designs were slightly modified for their different roles and in 1910 at least 1000 sets of apparatus were probably produced by Siebe Gorman for the Royal Navy Submarine Service. Most of the Hall-Rees-Davis apparatus would have been scrapped when it was superseded by the DSEA around 1927. There is no known account of the Hall-Rees-Davis apparatus ever being used in earnest to escape from a stricken submarine, but it did prove more useful in its shallow water diving role. During the period 1910-1927 some Hall-Rees-Davis shallow water diving apparatus was produced for the commercial market, but was of limited use in British waters (standard closed diving dress being more useful) and few examples have survived to this day.

References

Davis,

Robert H. 1909. A Diving Manual and Handbook of Submarine Appliances. 1st

ed. ‘Siebe Gorman & Co. Ltd., Boniface ST., Westminster Bridge Road, London

S.E.’ 184 pages.

British Admiralty. 1910. DIVING MANUAL. Siebe, Gorman & Co.’s ‘Manual for

Divers’: ‘G.14251/1909’. HMSO. 83 pages.

British Admiralty. 1916. DIVING MANUAL. Royal Navy Manual for Divers: ‘G.

24974/16’. HMSO. 88 pages.

Siebe Gorman & Co. Ltd. circa 1909–1932. Catalogue ‘D’. Diving Apparatus and

other Submarine Appliances. Siebe Gorman & Co., Ltd., “Neptune” Works,

London, S.E. 116 pages.

Davis, Robert H. 1948. Breathing In Irrespirable Atmospheres. Siebe

Gorman & Co. Ltd., London. The Saint Catherine Press, London. 386 pages.

Davis, Robert H. 1955. Deep Diving and Submarine Operations. 6th ed.

Parts I & II. Siebe Gorman & Co. Ltd. London. The Saint Catherine Press, London.

693 pages.

Davis, Robert H. 1957. A Brief Personal Record of the firm of Siebe Gorman & Co.

1819-1957. De Montfort Press. Leicester. 220 pages.

Stillson, George D. 1915. Report on Deep Diving Tests. Bureau of Construction

and Repair Navy Department. Washington Government Printing Office. 252 pages.

Acknowledgements

I would especially like to thank Peter Jackson (HDS) for his help and advice with this article. Also to Phil Thurtle and Mike Fardell for their help with requested information and photos.

With

Special thanks to Mike and Robert Burchett for all their research into this

article.