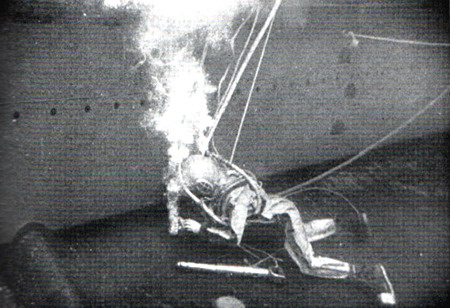

| A diver using a Cox Bolt Driving Tool. |

|

Prior to the invention of the submarine Bolt driving tool and punching

gun the diver may have spend many hours drilling, tapping and screwing

bolts into steel and wood. It quickly became an indispensable piece of

equipment for the underwater salvor. Repairs could be done in a matter

of hours rather than days. This became so important as it allowed the

salvor to recover valuable cargo before deteriation. In other cases a

temporary repair could be effected allowing the ship to be removed from

enemy exposure during conflict and from the conditions of the weather

and tide. The Bolt driving and punching gun could be used for a wide

varity of uses, operators often finding new uses for the tool. Patching

of large and small holes could be made and rivets could be tightened by

firing a bolt through them. Brackets, eye bolts and plugs could be

easily attached in a few minutes.

The gun was operated by an explosion which drove a solid or hollow bolt

into steel or wood. There was no recoil or flash with the gun under

normal operation. Whilst the solid bolt was used for fixing, the hollow

bolt could be used to attach an air line or the means of passing through

the plate of a cable. By fixing an air line to a submerged vessel it was

possible to supply trapped sailors with a vital air supply. The barrel

of the gun was loaded on the surface and lowered to the diver. Loaded

sealed barrels could be carried by the diver and inserted into the gun.

Providing the diver was fed with new barrels he could work continuously

and therefore complete the operation in a timely manner.

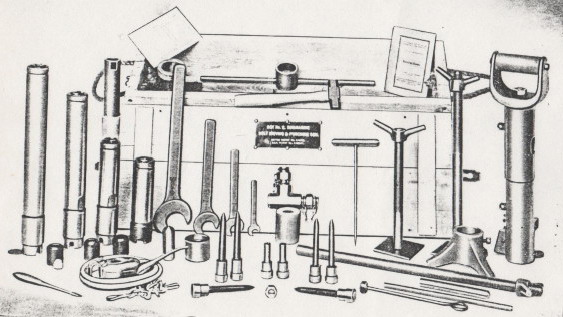

The gun comprises of a number of components and here we describe the Cox

Submarine Gun. There is one size, weighing 36 lbs. which comes with a

barrel for bolting and one for punching. There were 7 inch bolting and

punching barrels. The bolt ammunition was 5/8 inches in diameter and 4

1/2 inches long. The bolt was heat treated and made of alloy steel with

a tensile strength of 16 tons. A 3/4 inch plate required a force of 12

tons to fix through. The punch ammunition is 11/16 inches in diameter

and punches a hole to suit the size of the bolt. Extension bolts were

used for fixing patches of wood and were 1 inch in diameter. To these,

wing nuts could be attached. The weight of the gun as we have mentioned

earlier was 36 lbs, and could be tiring if many holes were to be

punched. To relieve the weight 2 eye bolts were attached to the gun and

springs or elasticated rope fixed. The gun was then lowered to a

position a couple of feet above the diver who could easily pull into

position for firing and then returned away from the work area.