The

Life of a Nuclear Diver

All

material in this article is copyrighted © by William L. Sheaffer

Introduction

Commercial

diving comes with its fair share of problems and challenges.

Disorientation, temperature, strong currents, depth, and low visibility

are a few of the challenges that divers face daily.

Now consider those are gone and a new challenge is presented, one that

cannot be seen, touched, tasted, or smelled.

This challenge is radiation and to a nuclear diver it is a very real and

potentially hazardous occupation.

In todayís world of heightened security due to the risk of terrorism, the

nuclear power industry is always on watch. For

a worker just to get through the door, a series of prerequisites must be

fulfilled. A psychological

evaluation, FBI back ground screening, drug screening, and many hours of

education are required. The

classroom training is on how the plant operates, fall protection, confined

space, foreign material exclusion, and of course, full radiation worker

knowledge. Once all these are

completed and accepted, an unescorted access will be granted and the worker can

then enter the plant property. To

enter the plant, the worker must pass through a bomb detector, a metal detector,

and then a key card gate that also requires the workerís hand geometry to be

scanned. Once past the guard house,

the nuclear workers can begin the role for with they were hired, nuclear divers.

Depending on the location of the dive operation, many hours of meetings with

engineers, radiation protection, and the client are required.

The dive crew must have a full understanding of the work location, work

to be performed, water temperature, water depth, and potential radiation dose

sources. Generally these meetings

are referred to as briefs, but by no means are they brief.

These briefs can normally take up to several hours and much patience, but

that is all part of the job.

In water temperatures exceeding 95 degrees F, a diver can quickly become

fatigued and run the risk of possible heat stress.

If the dive location is found to exceed this temperature level, several

options must be considered. The use

of temperature reducing gear for the diver is one option or the possibility of

postponing the job until temperatures can be reduced is another.

Normally the second option is not possible due to the time it would take

to reduce temperatures. So the

option of gear used by the diver is on the top of the list.

The modern nuclear diver has two reliable options to reduce the

temperature inside the suit, one is an ice vest and the other is a cool suit.

An ice vest is a good option if the dive will be short, since the ice in

the vest will melt, eventually causing the diverís temperature to rise.

A cool suit is a much better option since it is more reliable and will

keep temperatures low during the full length of the dive.

The cool suit was a joint design conducted by divers and astronaut suit

engineers, allowing for bottom times of over an hour in water exceeding 120

degrees F. It is a light weight

Dacron material with small diameter Tygon tubing sewn into the exterior of the

suit. The Tygon tubing allows for

chilled water to pass through, constantly keeping the diverís body temperature

much cooler than the surrounding water. The

chilled water is normally kept in a small cooler that is mixed with ice and

circulated to the diver using a small air powered pump.

On larger dive jobs involving more than one diver in the water at a time,

a refrigerator pump unit is used.

Radiation

Protection

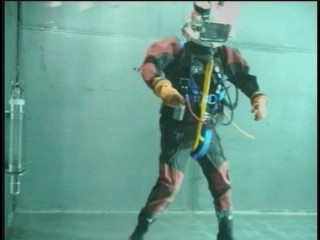

Before any diving can be done, a meeting with Radiation Protection (RPs)

needs to be scheduled so understandings between both groups can be

achieved. The RPs should have

up to date dose rates for the job location, so the divers know what they

can expect underwater. The RPs

and divers also need to agree upon where dosimetry packs will be placed on

the diverís body. The packs

are small electronic dosimeters (EDs) that record the amount of radiation

dose the diver is receiving. Each

ED is placed on a section of the diverís body, which normally is on the

feet, legs, chest, arms, and head (picture 1).

The EDs are linked by wires to a central transmitter unit usually

attached to the diverís back. On

the outside of the suit is a receiving unit antenna attached to a cable

mated to the dive umbilical. Topside

this cable is attached to a computer for the RPs to monitor in real time

the radiation field and the dose the diver has received.

This is one of the most vital portions of the nuclear diverís

equipment. If one of these

units were to fail, most likely the dive is terminated until the problem

can be located and fixed. |

Picture 1: Diver with

EDs attached

|

|

The

divers' outfit

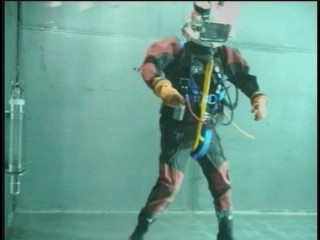

Picture

2: Diver in ďNukeĒ dress out |

On

the day of the dive it is time to get dressed up; the diver has on a cool

suit with all EDs attached to the outside.

As the diver marches up to the fuel floor, RPs are in tow to make

sure everything is ok and the EDs arenít bumped.

The rest of the dive crew has been on station for nearly an hour

now, to do their last minute checks and make sure everything is ready for

the diver. Once the diver is

on the floor, all attention is directed to the diver for a timely suit up

and water entry. The diverís

suit is made of vulcanized rubber (ex. Viking, Hunter..) which limits the

amount of contamination, is easily cleaned, and waterproof ďmost of the

timeĒ. The cool suit has

hook-ups inside the dry suit which look similar to the inflator valve on

any dry suit. On the exterior

of the suit is an identical hook-up which is attached to the cool water

hose. At this time the cool

suit will be hooked up to make sure the diverís cool suit is working

correctly and to start cooling the diver who is already beginning to heat

up. After the suit is zipped

up, two layers of rubber gloves are attached to the hard cuffs on the dry

suit. This allows the diver to

have dexterity while limiting the amount of contamination to the hands,

especially if the outer layer happens to rip.

Next up is the external antenna attached to the divers harness.

This will enable the RPs to verify all the dosimetry is working and

all the packs are transmitting. As

with normal dry suit diving, weight is essential, so on comes the heavy

belt with solid weights. In

the past small shot lead weights have broken and caused foreign material

issues, thus the reason for solid weights.

Last but not least is the helmet, which normally is a Desco air

hat, due to itís positive pressure free flow, and smooth cleanable

surface, it is the preferred hat for nuke work.

The suit is fitted with a Desco neck yoke that mates up to the hat

and makes a water proof seal. Once

the hat is on and cammed up the diver quickly but safely enters the water,

that is a lot of weight to have on in the dry (picture 2). |

The Amp 100

| Once

the diver is in the water, an Amp 100 is lowered.

The Amp 100 is a radiation sensing device that allows the diver to

give a more accurate survey of the work area.

This device is also very useful for acquiring dose rates on items

that might be found on the bottom. Due

to the possibility of irradiated items, this will tell the diver if that

item can be picked up or just pushed off to the side.

After the RPs have given the ok, the diver can then proceed with

the objective at hand (picture 3)(picture 4)(picture 5).

If dose rates are found to be higher than expected an underwater

vacuum can be used to help remove contaminates from that area.

If a vacuum is not an option, the placement of lead blankets can be

used to help lower the amount of dose the diver will receive.

|

|

Picture 3: Using an Amp

100

|

Picture 4: Diver at

work

|

Picture 5: Diver

welding

|

Once

the diver has completed the assigned task, it is time to clean up the work area.

The tenders will start to bring items up to the surface as with normal

clean diving operations. As these

items are being raised, anything coming out of the water must be rinsed with

de-mineralized water and wiped down. Thoroughly

cleaning these items will ensure the prevention of the top side personnel from

being exposed to potentially hot particles.

Hot particles are small bits of irradiated material, which are usually

too small to see with the naked eye. If

these particles are left out of their water shielding, it could cause extreme

dose to be received by the workers. After

all the tools and equipment are cleaned up, itís time for the diver to come

up. As with everything leaving the

water the umbilical and the diver must be washed down.

Special attention must be placed on rinsing the diverís hands and feet

which come in the most contact with contaminates on the bottom.

Once the diver is clear of the water, the tenders and RPs go into action.

The tenders quickly wipe the diver down, trying to get all drops of water

off the suit. While the tenders are

drying, the RPs are using meters to survey the diver and assure there are no hot

particles on the suit. By this time

the diver is tired, so in reverse order of donning the equipment, the tenders

assist in quickly but carefully removing the gear.

Once clear of all the gear the diver is marched back off the floor by the

RPs. They will first ensure there

are not contaminates on the cool suit or dosimeters, if clean the packs are

removed and the diver is clean to change back into clothes.

If the diver is found to be contaminated, then itís off to the showers

to clean up and hopefully make it past the radiation contamination monitors,

thus ending another nuclear dive (picture 6).

|

Picture

6: RPs & Tenders in action

|

Conclusion

Over

the many years, the nuclear power industry and commercial diving companies have

been working together to form a state of the art partnership.

Cooperation by both groups have developed solutions to problems in a more

practical format. Instead of

draining an entire pool to perform a job that would be costly to the plant and

cause extreme dose rates for its workers, divers have been implemented.

When emergencies happen, divers are usually the first to be called in to

assist. They have worked in spent

fuel pools, performing re-racks, which allow for more storage of spent fuel

rods. Theyíve gone into fuel

transfer canals to replace sensors and repaired broken transfer carts which move

the fuel bundles. Theyíve welded

on steam dryers, which have been cracked and needed modifications.

Theyíve mended broken equipment above the reactor which would have left

the plant in a complete shut down unless repaired.

Theyíve even worked in the reactor several feet above live fuel to

repair flow nozzles, and recover lost items which could damage the fuel rods.

All the while performing their work as professionals even knowing that

for each day the plant is not producing power, itís loosing upwards of a

million dollars a day. No time

pressure!

About the

DESCO air hat

When

diving in a nuclear plant, time and cost become a huge factor in planning for

work. As stated in the Nuke diver

article, a nuclear plant can loose upwards of a million dollars a day, when it

is not producing power. If the

diving operations are in the power producing areas, the divers will be under a

magnifying glass. The divers will be

expected to perform their work quickly and efficiently, and questions will arise

when they fall behind planned hours. To

decrease down time due to diver problems, the Desco air hat has been found to be

one of the easiest hats to maintain in the field.

With its basic engineering, any repairs that may arise, can be dealt with

rapidly and normally will be back in the water in less than an hour.

As stated before, the other issue with nuclear plants is cost.

When diving in radioactive pools, any dive gear that comes in contact

with the water is regarded as contaminated.

Also depending on the dive station location and potential for airborne

contaminates, that too may be contaminated.

All this contaminated equipment can no longer be placed back into normal

service. If the equipment is new and

brought into the plant by the diving contractor, then the plant becomes the

proud owner of this diving equipment. Since

diving gear is not cheap, they look for the contractor to lean towards less

costly equipment. Dive umbilicals,

radios, harnesses, and weight belts are normally at a set price, but helmets can

come cheaper, thus the Desco air hat.

As

with normal diving, it is not uncommon for the diver to hit his head on a

support or obstruction. Through out

the industry fiberglass helmets have been seen with scrapes and gouges on the

surface that will attract dirt and other debris.

In a nuclear pool, the debris now becomes radioactive contaminates, that

may be hard to clean off, in turn raising the acquired dose on the helmet.

The copper of the Desco air hat is a much nicer and easier material to

clean, even with the scratches, helping to keep dose rates lower.

The last thing the diver and the plant want is a high dose source on the

head.

Another

benefit of the Desco air hat is its positive pressure, free flow design.

In the event the neck ring leaks, the positive air will push out the

leak, and prevent water from entering. Even

if the diver is working hard, the chance of the diver over breathing the hat

causing a negative pressure is slim. The

potential for leaking hats is always on a divers mind, and it has happened, but

for the majority of all nuclear dives, the head is the driest part of the body.

I

hope this sheds a little light on what type of diving helmets the nuclear side

prefers. The Desco air hat is the

preferred hat in the

US

, but through out the world, other hats are being used and I have no intention

on down playing other manufacturers helmets.

This article is based on what my company dives and what Iíve had

experience with the length of my nuclear diving career.

Many

thanks to Bill Sheaffer for his fantastic help on this part!

Continue

to page 2 to see more Nuclear divers in action

Related topics

- Last edited 28th March 2011