SVV-55

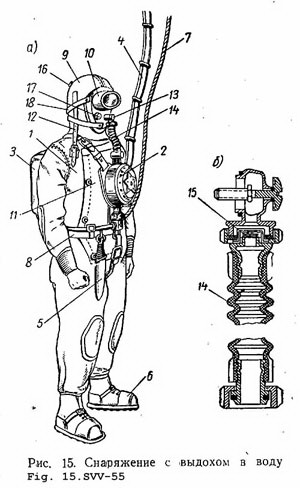

The SVV is equipment for underwater use and was developed around 1955.

Expired air from the SVV-55 passes into the water through a special exhaust valve.

The SVV-55 equipment was used for depths up to 15 meters with an air supply from a compact air pump or for 25 m and greater using a motor compressor or another powerful air source.

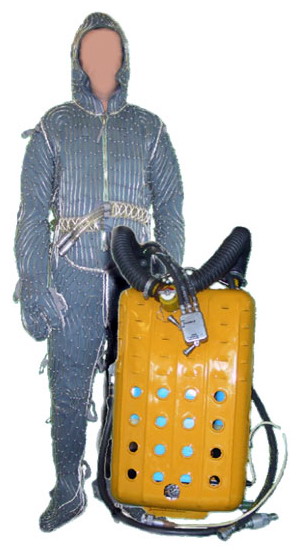

SVV-55 kit consists of a diving suit GK-3 (see Fig.15) 1, a breathing device 2, an emergency device 3, a diverís hose 4, a diverís knife 5, diverís boots 6, a signal rope 7, a belt 8, and diverís underwear. The SVV-55 set may also have telephone equipment.

The complete TSLV type with cable, lightweight air pump and spare parts with instruments was also available.

The diverís suit GK-3 is made from a three-layered rubberized material and produced in one size (length) only. The diverís suit has a volumetric helmet, 9 with semi-rigid rubber mask and a metal ring with eyeglass, 10 mounted in the upper part of mask.

The diver dresses into the suit through wide, sleeve-like extensions, which are called the appendix. The appendix ends in an opening in the right hand side of the suit chest. The appendix is closed by a rubber cord, covered with a protective apron11, and by four clasps. The inside of the suit opening is covered with an inner apron also.

Straps with buckles 12, are used for pulling down the helmet with the purpose of decreasing the air space inside of the helmet.

There is a connecting pipe mounted in the lower part of mask. The breathing part of the mask joins to this connecting pipe inside the mask with a small pipe 13, and the inhaler-corrugated pipe 14, is joined to it outside. A micaceous inhalation valve 15, on upper side of inhalation pipe blocks the way for exhaled air to be re inhaled.

The exhaust valve 16 is on the upper part of helmet. This valve lets the air out from the diver suit and volumetric helmet. It has two positions: ďopenĒ and ďclosedĒ. The exhaust valve works as a safety valve in the ďclosedĒ position. It starts to work if the pressure inside exceeds the external pressure by 0.1 atmospheres (1.5 psig).

Diverís exhaled air leaves from right side of mask 17.

The half mask is attached inside of helmet mask and covers half (mouth and nose) of the diverís face. The half mask is held to the face by straps 18 and seals the air inside of helmet.

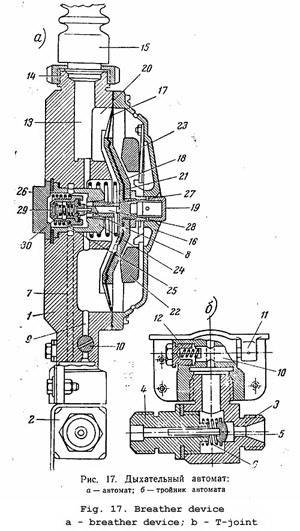

The breathing device structure is especially interesting (see Fig. 17). The breathing device compensates for pressure of the inhaled air according to the diverís body position.

The breathing device has a T-joint with 2 with two connecting pipes - 3 and 4. The diverís hose attaches to the connecting pipe 3 whilst the emergency device, which is placed behind diverís back, attaches to connecting pipe 4.

The T-joint has a non-return valve 5 which blocks the way for air from breathing device if diverís air supply is interrupted.

Air from the T-joint goes to the breathing device by two routes: along canal 7 through breathing valve 8 and along canal 9 through hole in plug of direct air supply valve 10. Plug of direct air supply valve is controlled by lever 11.

Air goes along canal 13 through outlet connecting pipe 14 and along inhaler pipe 15.

There is a rubber diaphragm between the device body and cover 16. There is a button 19 on the diaphragm to push for a manually controlled air supply. Diaphragm 17 isolates inside hollow of breath device 20 against the ingress of water.

The spring 21 presses on the diaphragm from one side and water pressure presses through holes in the cover on the other side. There is lead lever 22 under cover and over the diaphragm. It is attached to a leaf spring 23. When the diver is on his back, this load applies extra pressure on the diaphragm from outside and makes it easier for the diver to inhale.

Air is supplied from the surface along the diverís hose to connecting pipe 2 of the breathing device. Air opens the non-return valve in the T-joint and goes along canal 7 (canal 9 is closed) to inhaler valve 8.

When the diver inhales, the pressure falls inside the hollow tube of the breathing device 20. The diaphragm concaves by the greater water pressure, compressing the springs 21 and 25, and pressing on rod 28 and opens thereby the inhaler valve. Air goes through slanting holes of the sleeve, fills hollow under diaphragm and goes to inhale mode by canal 13, outlet connecting pipe 14 and inhaler pipe 15.

When the inhalation stops, the air continues to feed goes under the diaphragm until the inside pressure is equivalent to the ambient pressure. The diaphragm returns to the middle position by the pressure of the spring 21. The inhaler valve then is closed by the pressure of the spring 25. The air inflow in the hollow of breath device is stopped.

The diverís exhaled air exits through the exhaust valve.

The breathing device is force loaded also. The weight of breathing device is 10 kg.

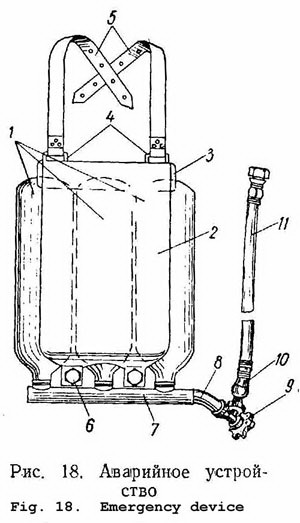

An emergency device (see Fig.18) is needed if the surface air supply stops suddenly, for example if the diverís hose is interrupted. This device is mounted on the back of the diver. The weight of emergency device is 14 kg.

The emergency device consists of three 1.3-liter canisters 1, charged to 200 atmospheres working pressure. The canisters are placed into a metal casing 2.

The diverís boots are lightweight, the weight being 10 kg.

From book: ďRIVER FLEET DIVERĒ / Kuznetsov I. I., Moskow, RIVER TRANSPORT publisher, 1962.

Translated by Konstantin

Korchagin, club ďSADKOĒ, Nikolaev, Ukraine.

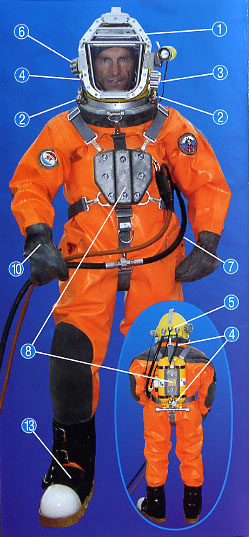

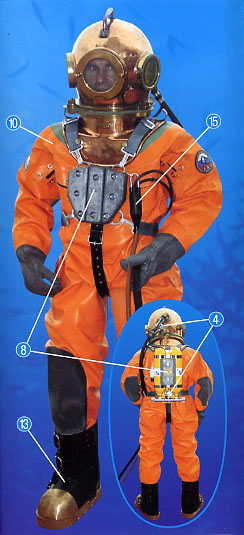

SVV-86

This equipment was designed for work at depth up to 60 meters of water ranging in temperature from 0 to 30 degrees (Celsius).

Source: Russias Weapons Catalogue Volume III : Navy

Many thanks to Andrei Iachine from Moscow Russia for his help on this part.